To take care of optimum performance, functions management desires to monitor critical steps, evaluate work strategies and techniques, and take motion when troubles come about. In doing this, it's going to become important to partially or entirely revalidate a process.

Masking lots of manufacturing sorts, the ISPE Very good Apply Manual: Functional Implementation in the Lifecycle Method of Process Validation is really a reference of technological and scientific depth to help organizations conduct process validation from scientifically audio development to robust reliable processes. It is intended to assist corporations in knowledge the applying of worldwide regulatory validation needs by delivering step-by-step implementation methods to PV and leveraging process being familiar with to advertise very best techniques.

Once the process has been experienced, the 3rd stage concentrates on ongoing monitoring and evaluation from the process general performance making sure that it continues to be in control.

Specified man or woman from QC shall verify The correctness of carried QC tests at different process stages and availability of essential testing methodology .

In nowadays’s pharmaceutical field, process validation depends on info and expertise from solution enhancement things to do to make sure individual prerequisites are translated into products characteristics. A vital to good results is setting up a comprehensive science-based mostly process layout that focuses on understanding sources of variability.

In this particular stage, the process is developed and documented in detail. The crucial process parameters as well as corresponding working ranges are recognized.

Ongoing process checking is additionally a crucial prerequisite outlined via the EMA. This involves the frequent monitoring and Assessment of process details to make certain the process continues to be within a here point out of Management.

It also needs to deal with the validation of crucial process parameters as well as the validation of analytical approaches utilized to assess item high quality.

One of several inputs to a call to revalidate may be a potential effect to some essential process parameter That may provide a couple of alter in product or service high-quality or create a new danger. One more enter can be a alter to a regular that relates to the process.

Throughout the process structure stage, it is very important in order that all areas of the process are extensively recognized and documented. This features not merely the specialized requirements but additionally the probable impression of varied variables to the process performance.

By way of example if there isn't a improve in whole lot sizing click here at Granulation stage and only amount of heaps amplified,

Cycle analyze ranges shall perform for your minimal, the best possible and most ranges and Document inside the attachment of respective batch amount.

Even though the OQ is remaining conducted, you’ll desire to conduct several other checks to ensure They are really working with specified ranges. These incorporate process controls, voltage and amperage concentrations, computer and computer software techniques, environmental problems (e.

Data integrity is another important facet emphasized via the EMA. The suggestions anxiety the importance of maintaining accurate, complete, and dependable details through the validation process. This contains ensuring suitable documentation practices, facts traceability, and information integrity checks.

Bug Hall Then & Now!

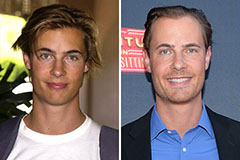

Bug Hall Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Nancy McKeon Then & Now!

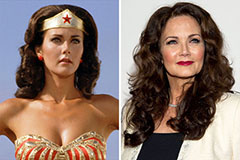

Nancy McKeon Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!